-

Company

-

Technology

-

Portfolio

-

Contact us

Company

Top solution provider for mass transfer processes

-

About us

As a mass transfer specialist, Benit M provides the optimal solution to improve the performance …

-

History

Benit M was established in March 2016 in Ulsan, Korea. Since June 2016, Benit M has been ...

-

R&D

We are conducting profound research resulting in acquiring the worldwide patent rights …

Technology

We are committed to spreading technology and expertise in the mass transfer process around the globe while sustaining true quality of the values

-

Distillation Engineering

Solutions from basic design to column design, including advanced distillation

-

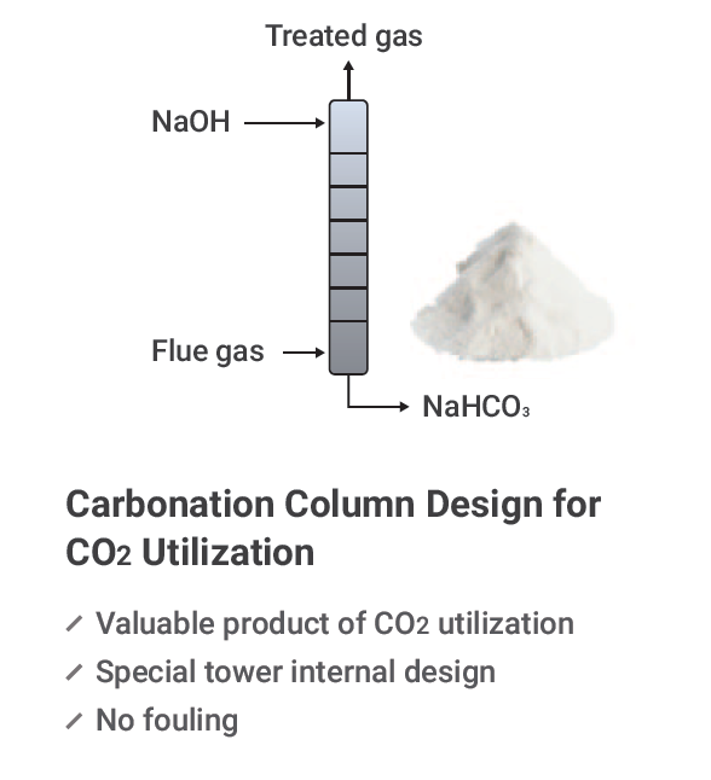

CO & DeSOx

Process and equipment design to solve problem associated with gas emissions

-

Desalination /

Pure Water Production SystemNovel technology to improve the existing pure water production and desalination technologies

Portfolio

We have continuously conducted valuable projects and deliver the highest values to our clients, and the synergies has been created to become a lifetime partner with the clients.

Projects Portfolio

read more

References

read more

-

Process Basic Design for Methanol Recovery from Waste MeOH

Fine Chemical

2025-03

-

LCO2 Process Vent CO2 Recovery System Basic Design

Hydrogen

2025-02

-

Semiconductor Grade LCO2 Process Optimization Basic Design

Hydrogen

2025-02

-

POE Commercial Plant Distillation Process Basic Design

Petrochemical

2024-04

Benit M’s Client Map

Explore our activities for various type of client

-

read more

Contact us

We look forward to working with you and answering any questions you may have.

-

News

read more

-

Successful Industrial Application of Enhanced Active Vapor Distributor in Dividing Wall Column

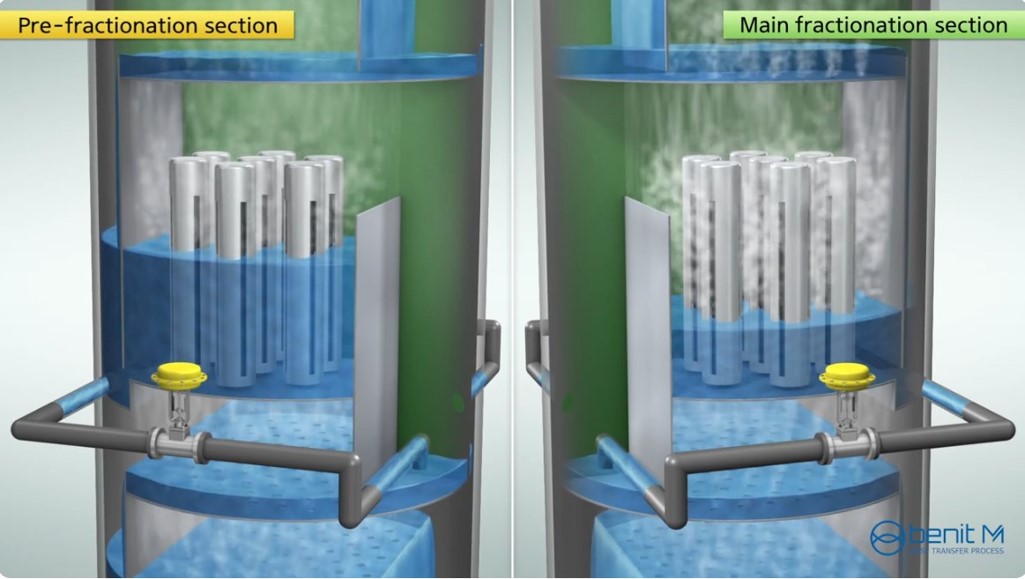

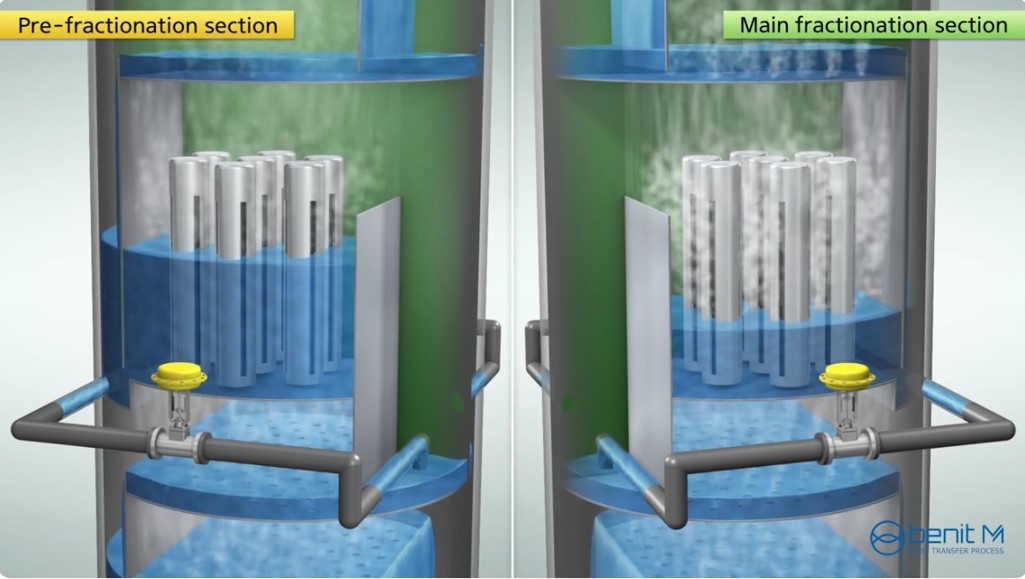

Benit M performed basic design to compose the fractionation process for semiconductor-grade high-purity solvent production.This process was designed to include a Dividing Wall Column(DWC) to accommodate all equipment inside the limited plant area and to save energy.EAVD® was installed in the DWC to control vapor split ratio. Startup operation was completed in July 2025, successfully.The client was satisfied with the performance and easy operability of the DWC.EAVD® operated to compensate 0.3 ~18.8 torr pressure drop difference between the pre-section and main-section while controlling vapor split ratioby adjusting the liquid level in EAVD®from 10% to 76%, depending on the operating mode.

2025-10-10 -

Discover the Benefit of Waste Heat at INDO WATER 2025 - Meet us at Booth BC21

Benit M invite you to the INDO WATER 2025 EXPO & FORUM,August 13–15, 2025 | 10:00 AM – 6:00 PMJIExpo Kemayoran, Jakarta | Booth No. BC21We’ll showcase our patented FO-PV Combined Membrane technology, which desalinate seawater and produce pure water with quality <1.0 µS/cm,using only low-temperature waste heat (70–100 °C), with no high-pressure pump required.Also featured in this exhibition:- CO2 capture, liquefaction, and utilization technologies- Cost-effective distillation solutions, including our energy-saving DWC with EAVD® technologyLearn more: https://m.youtube.com/@benitm9390/featuredIn addition, we also invite you to our technical presentations on the aforementioned technology:1. Wednesday, August 13 | 15:00–15:45 @ Theater 12. Thursday, August 14 | 14:00–14:45 @ Theater 2Please register for free through this link: http://visitorreg.id/We look forward to welcoming you.

2025-07-30 -

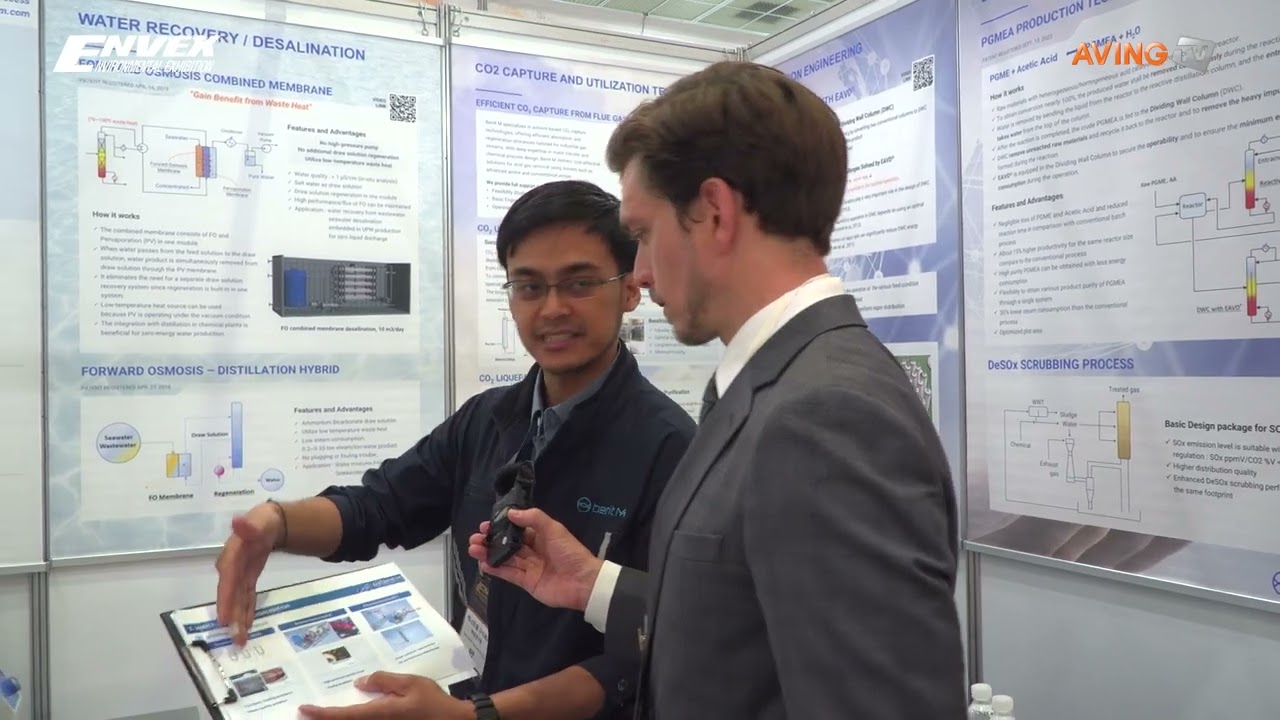

FO combined membrane technology is featured in AVING News

Benit M’s innovative forward osmosis–pervaporation (FO-PV) combined membrane system was prominently featured on AVING News following its live demonstration at ENVEX 2025, held June 11–13 at COEX, Seoul.Highlights of FO-PV combined membrane in AVING News1. Utilization of Waste HeatBenit M’s technology operates using low-grade waste heat (70~100°C) or solar energy without the need for an external heat source. This enables economical and sustainable production of high-purity water.2. No Need for High-Pressure PumpThe system runs effectively with standard industrial pumps at 3–4 bar, eliminating the need for high-pressure pumps typically required in reverse osmosis systems. This significantly reduces mechanical complexity, energy consumption, and maintenance costs.3. No Draw Solution Regeneration RequiredThanks to the forward osmosis–pervaporation hybrid design, the system does not require draw solution regeneration, which is essential in conventional FO setups. This simplifies the process, reduces plot area, and further improves energy and cost efficiency.To get more details information about the FO-PV combined membrane on AVING news, please click the following link.https://kr.aving.net/news/articleView.html?idxno=1800752 https://www.youtube.com/watch?v=SxB6byU16BM

2025-07-17

-

-