An effective method of utilizing waste heat

Minimize heat loss

Energy saving by 35 - 65% (double, triple)

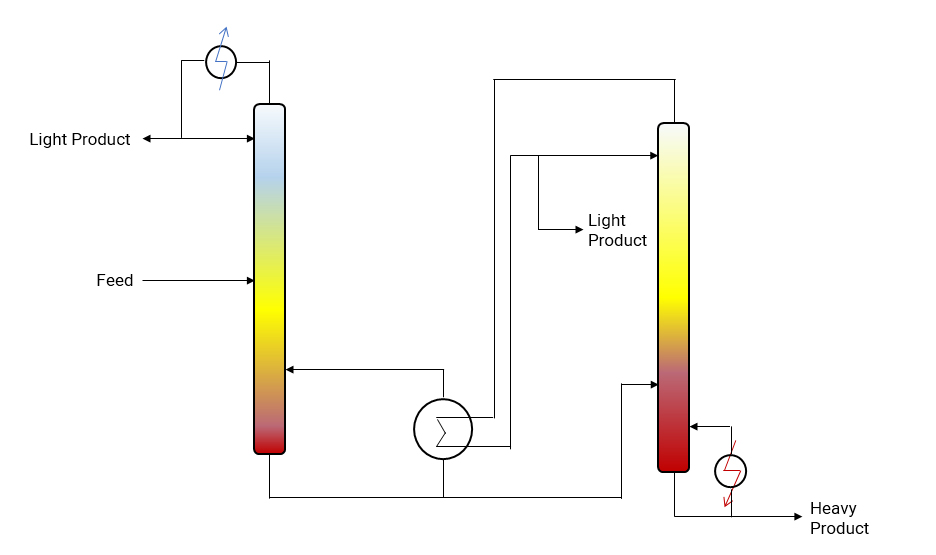

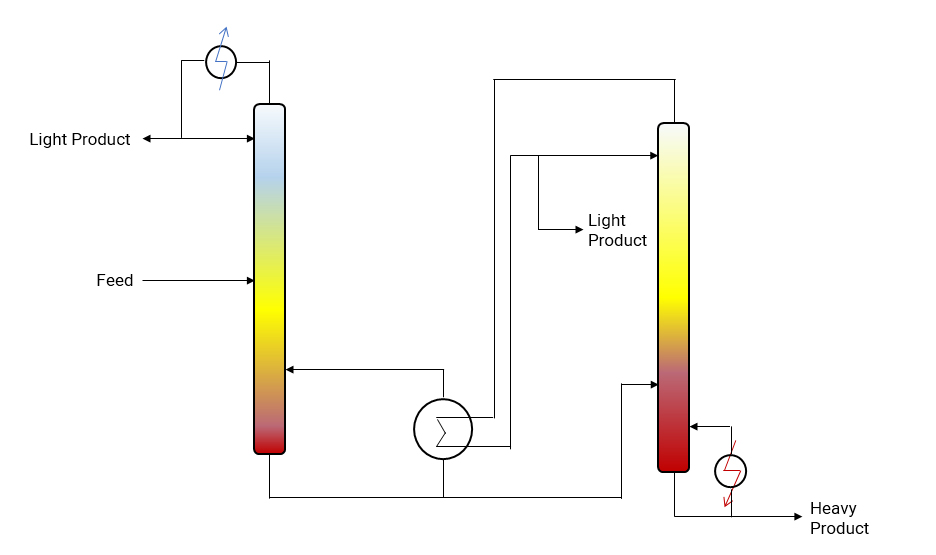

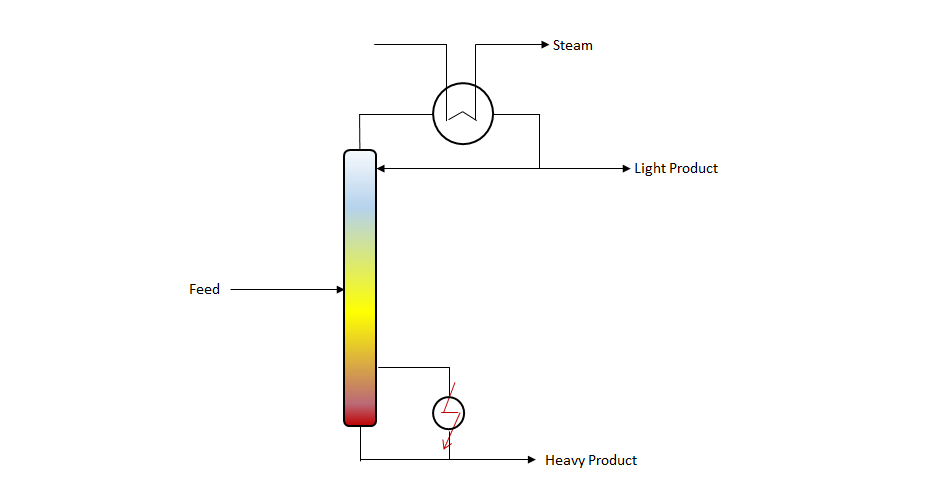

Distillation is a process that repetitively boils liquid stream and condensates vapor stream from bottom to top at each stage for the separation of components.

One approach for conserving energy in distillation is to reduce the total amount of energy input to the entire system by heat integration.

Multi-effect distillation is one of the ways to reduce the energy in distillation column by integrating two columns that operates at different pressure. It utilizes the energy from the vapor of one column as the heating source for the reboiler of the other column. It remarkably enhances the energy efficiency of distillation process.

Benit M patented a multi-effect distillation design which integrates the azeotropic distillation and conventional distillation. It is expected that this technology can decrease energy saving up to 65%. The multi-effect distillation can be used for many applications either grassroots or retrofitting projects.