Technology

-

Desalination / Pure Water Production System

Forward Osmosis combined membrane

Novel technology to produce pure water from seawater

Technology trend

Experts have been making efforts to improve the desalination technologies regarding water quality improvement, reducing installation space, CAPEX/OPEX savings.

-

Technology trend in desalination and associated problems are as below.

1st generation: Multi-effect Evaporation. (corrosion and fouling problem in the tube)

2nd generation: Reverse osmosis. (water quality problem, high-pressure pump problem, membrane fouling, membrane damage)

-

3rd generation: Forward osmosis. (preferable to Reverse Osmosis because of the low operating pressure. However, extra space is required due to the requirement of additional process/equipment for draw solution regeneration) Water flux rate decreases inside Forward Osmosis (FO) module because of the concentration gradient.

Therefore, new technology is in need to promote the usage of the preferred FO technology by solving the aforementioned disadvantageous problems.

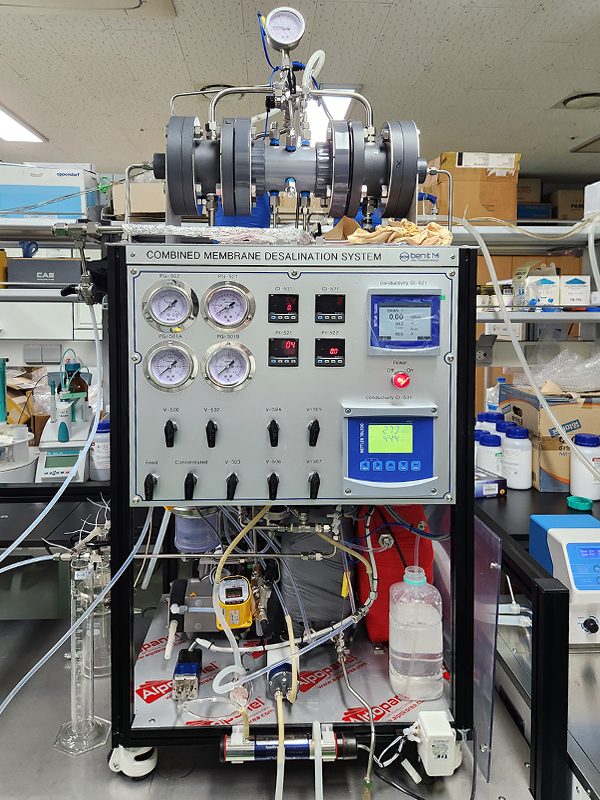

Forward Osmosis Combined Membrane

Produce pure water

Utilizing low temperature waste heat

Utilize 70 C ~ 100 C Waste heat.

Water quality : < 1 μS/cm (in-situ analysis)

Salt Water can be used as draw solution.

Draw solution regeneration in one module.

Prevent FO performance deterioration.

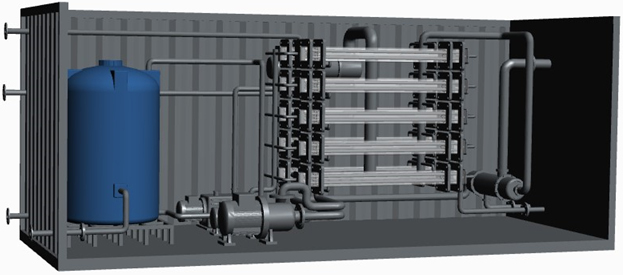

No additional draw solution regeneration apparatus.

Patent Registered 2019.04.16

FO Combined Membrane can be integrated with distillation column

FO combined membrane system embedded in Ultra pure water production system

Ultra Pure water production system commonly is composed of Pretreatment, Primary treatment, and Polishing stages.

As Benit M’s Forward Osmosis combined Membrane system can produce pure water, < 1 μS/cm, with one step using low temperature waste heat even from seawater. This pure water system can replace the existing Primary treatment stage of Ultra Pure Water system which requires several steps of Reverse Osmosis membrane.

Ultra pure water production system flowchart

Benefit of Forward Osmosis Combined Membrane

Forward osmosis combined membrane system does not require the additional system to recover the draw solution, because the regeneration function is built in the one module.

The combined membrane consists of Forward Osmosis and Pervaporation within one module. Three separated flow channels exist in one module. The one is for the feed solution, the feed chamber, draw solution chamber, vacuum chamber.

When the water passes from the feed solution to the draw solution, the water product is simultaneously removed from the draw solution through the pervaporation membrane. Therefore, the draw solution is not diluted by the water flowing through the forward osmosis membrane. For that reason, the water flux through the forward osmosis membrane can be maintained at the high rate.

To get the product, the pervaporation is operating under the vacuum condition so that the water vaporizes at below 90℃. Consequently, the low temperature waste heat or the conventional solar heat recovery system can be utilized to produce the high purity water < 1 μS/cm.

The integration of FO Combined membrane with distillation column in chemical and petrochemical plants might be beneficial for the water recovery from wastewater. By utilizing the energy from the overhead of the column, the water can be obtained as the product and the valuable chemicals can be recovered to minimize the chemical loss.

Forward Osmosis combined membrane can be used to produce boiler feed water and drinking water in ship utilizing low temperature waste heat from the engine.