-

Company

-

Technology

-

Portfolio

-

Contact us

Company

Top solution provider for mass transfer processes

-

About us

As a mass transfer specialist, Benit M provides the optimal solution to improve the performance …

-

History

Benit M was established in March 2016 in Ulsan, Korea. Since June 2016, Benit M has been ...

-

R&D

We are conducting profound research resulting in acquiring the worldwide patent rights …

Technology

We are committed to spreading technology and expertise in the mass transfer process around the globe while sustaining true quality of the values

-

Distillation Engineering

Solutions from basic design to column design, including advanced distillation

-

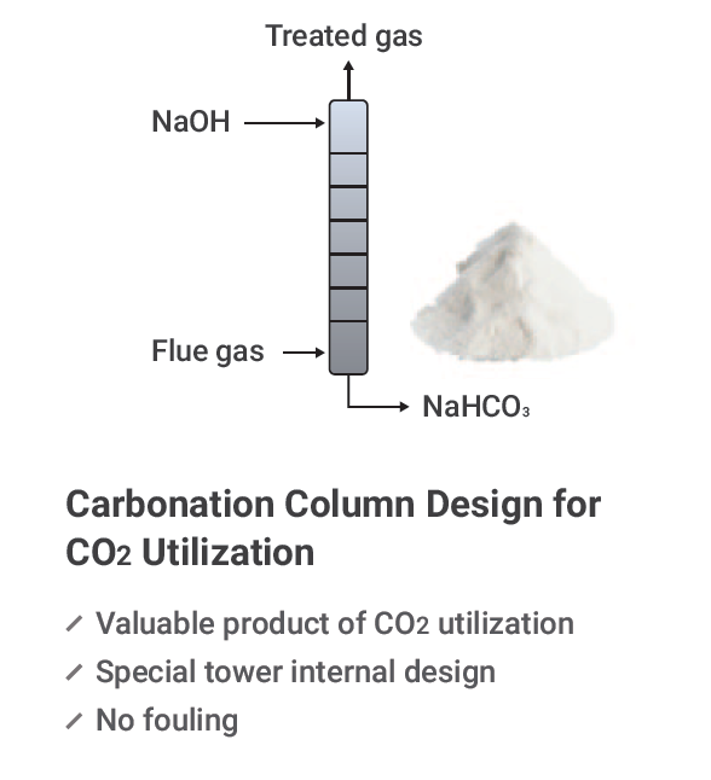

CO & DeSOx

Process and equipment design to solve problem associated with gas emissions

-

Desalination /

Pure Water Production SystemNovel technology to improve the existing pure water production and desalination technologies

Portfolio

We have continuously conducted valuable projects and deliver the highest values to our clients, and the synergies has been created to become a lifetime partner with the clients.

Projects Portfolio

read more

References

read more

-

Process Basic Design for Methanol Recovery from Waste MeOH

Fine Chemical

2025-03

-

LCO2 Process Vent CO2 Recovery System Basic Design

Hydrogen

2025-02

-

Semiconductor Grade LCO2 Process Optimization Basic Design

Hydrogen

2025-02

-

POE Commercial Plant Distillation Process Basic Design

Petrochemical

2024-04

Benit M’s Client Map

Explore our activities for various type of client

-

read more

Contact us

We look forward to working with you and answering any questions you may have.

-

News

read more

-

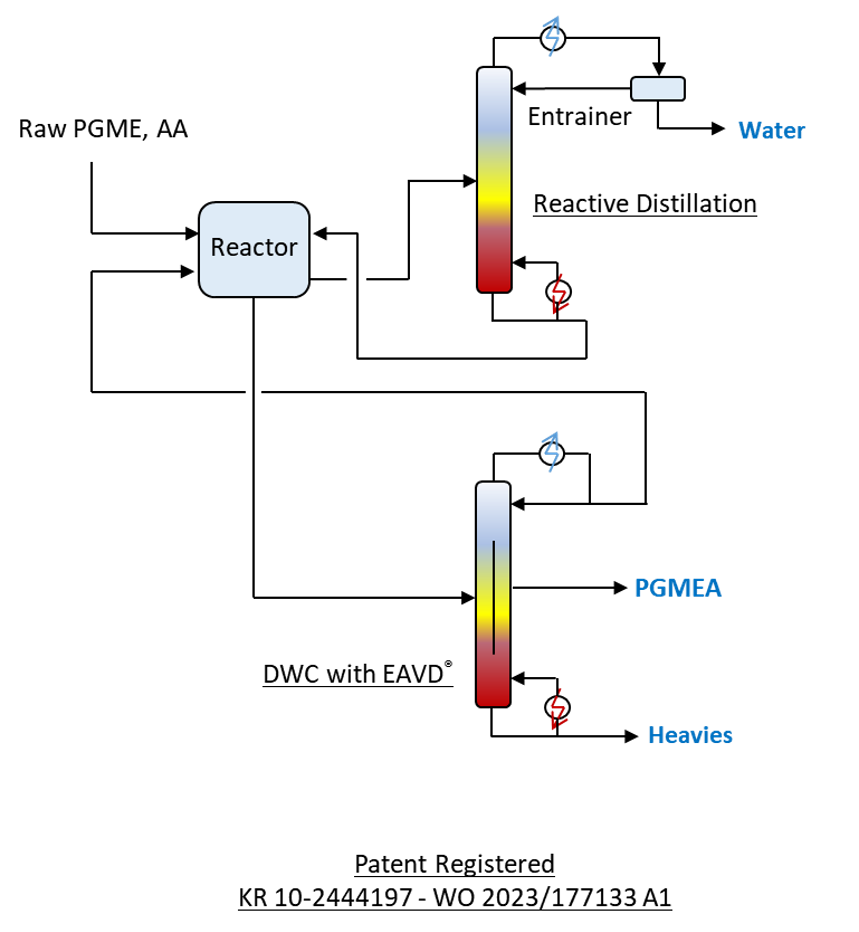

Patent registered: Method for Removing Water from PGME, PGMEA, and Water Mixture

Benit M offers its well-proven and cost-effective PGMEA production process with the basis of reactive distillation and dividing wall column technology to expand the PGMEA production capacity around the world, particularly to support the emerging technology of display and semiconductor material manufacturing industry.The following benefits can be obtained using Benit M’s technology:Negligible loss of PGME and Acetic Acid reduced reaction time in comparison with conventional batch processAbout 15% higher productivity for the same reactor size compare to the conventional processHigh purity PGMEA can be obtained with less energy consumptionFlexibility to obtain various product purity of PGMEA through a single system30% lower steam consumption than the conventional processOptimized plot area

2022-09-13 -

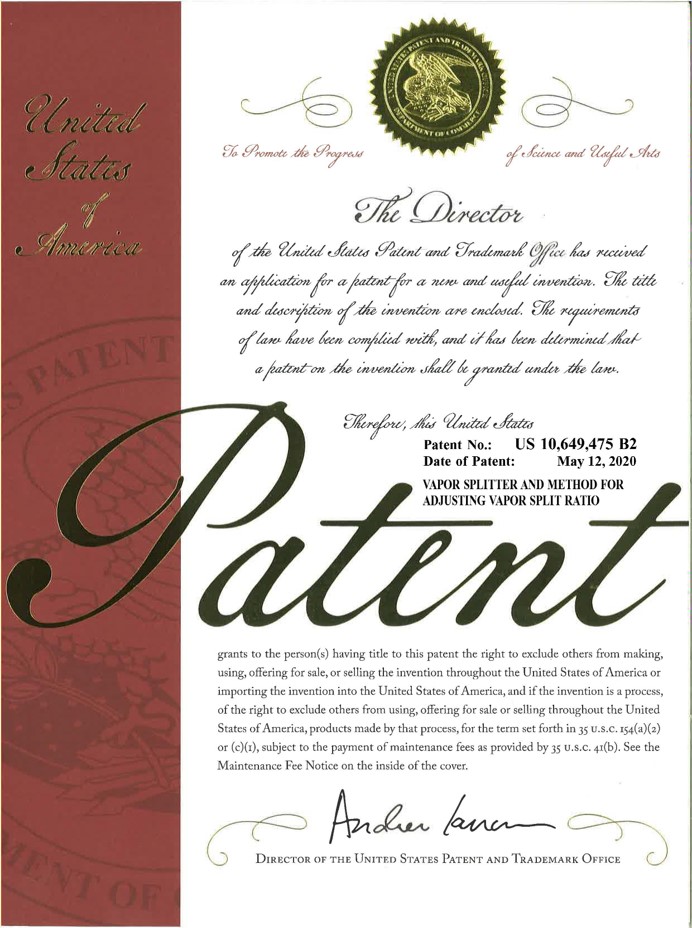

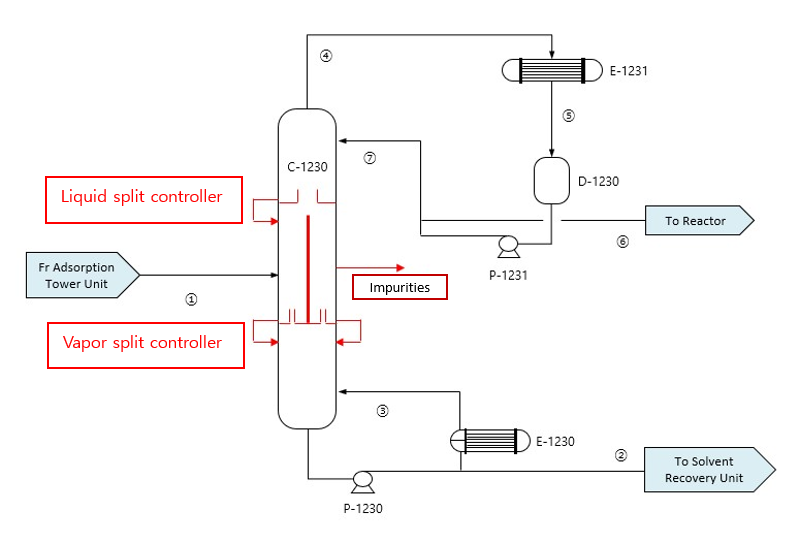

EAVD patent is registered in United States

We are glad to announce that EAVD is registered as a patent in United States under the title “Vapor Splitter and Method for Adjusting Vapor Split Ratio”.EAVD is Benit M’s invention which enables the vapor split ratio control for the Dividing Wall Column during operation.To find more about EAVD, please see this video. https://tinyurl.com/EAVD-video

2020-05-13 -

DWC Feasibility Study Project for New Chemical Plant to Achieve Energy Saving

Benit M carried out a distillation system feasibility study before client conduct the basic design for a new chemical plant. The purpose of the feasibility study was to determine the cost-effective process.By changing the operating mode of the column of the conventional process, the feasibility study concluded that 48% duty saving can be obtained. The study about the benefit of use side reboiler and feed flash drum have been conducted, as well.More specifically, Benit M studied the possibility of DWC application for the process, to reduce energy consumption while removing the impurities. The feasible process design and size of major equipment have been reported to the Client for the further design phase.

2019-12-30

-

-